The high frequency (HF) welding process, also known as radio frequency (RF) welding, combines materials by supplying them with high frequency energy in the form of an electromagnetic field (27.12 MHz) that is produced between two metal electrodes.

HF welding must be accompanied by a certain pressure on the material surfaces to be joined, and this is also how HF welding machines are designed.

Welding or HF welding is based on the unique properties of the welded material, which generates heat in a rapidly changing electric field, the so-called dielectric heating of the welded material.

This means that only some materials can be welded using this technique, including, of course, the materials used in the production of hydro BANKS , in which the dynamic electric field causes oscillation of the polar molecules (molecules) of the material.

Depending on their geometry and dipole moment, these molecules convert part of this oscillating motion into thermal energy and cause the material to heat up and weld.

The great advantage of HF welding technology is speed, because the material is heated from the inside and melts quickly within a few seconds.

Compared to HF technology, in all other welding methods, such as filaments, hot air or infrared radiation, heat is not generated inside the material, but is supplied from the outside.

This means that the heat must first penetrate the material to make it ductile enough to form a weld. The main danger of this type of processing is the burning of the welded material layer, which reduces its strength.

In turn, the HF technology triggers the heating of the material, without external heating. The generated heat causes the materials to melt and integrate firmly.

After cooling the welded surface with the maintained, properly selected pressure, the material is fused and an extremely strong weld is formed.

Importantly, the high-frequency weld is as strong as the surrounding material itself, or even stronger.

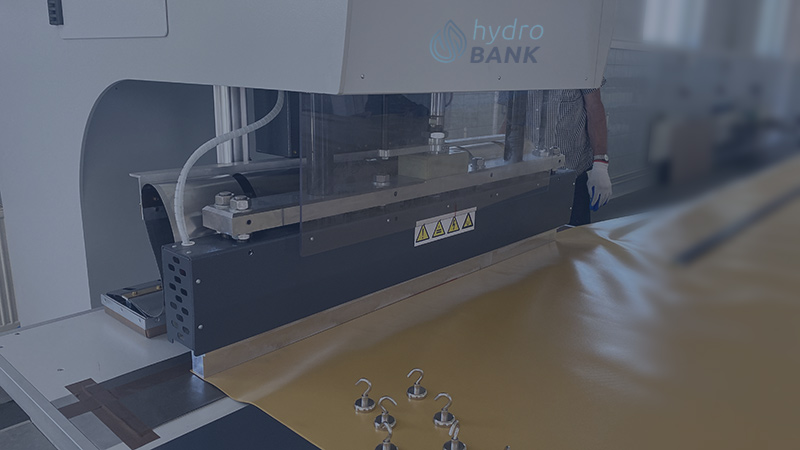

Our automatic HF welder consists of a high frequency generator (which produces radio frequency electricity), a pneumatic press, an electrode that transfers the radio frequency current to the material being welded, and a welding table that holds the material in place.